Air Control Units (FRLs)

VAC is a specialized company that manufactures pneumatic components. Our company integrates designing, manufacturing and sales service together and has set standards in the industry in less than 8 years.

When you buy a VAC product, you are quality as it's the critical factor in us. We ensure the highest standard in the industry as our products go through stringent tests and research to ensure wide acceptance. We make sure, our products are best in quality and pricing. For more about For more details about the Product Technical Specifications, Inner Structure and Dimensions - Click here and Download the Product Catelogue.

Options: Available in various options. Port Sizes: Port (Thread) Sizes available from M5 to 1". Filter Micron Rating: Standard available 40Micron & 5Micron. Customized Micron Ratings also available like 0.01Micron, 1Micron. Applications: Heavy Duty construction suitable for most applications. Max. Inlet Pressure: 16Kg/cm2. Max. Outlet Pressure: 12Kg/cm2.

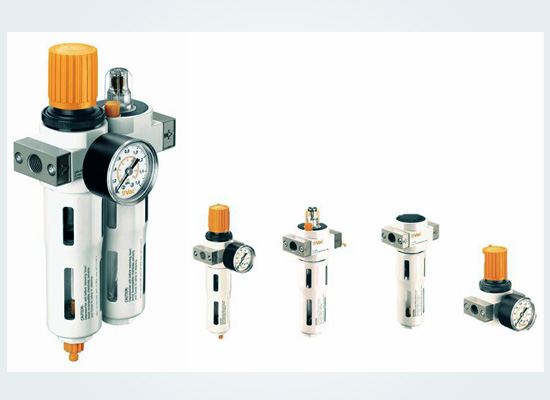

1. New Generation Air Control Units (FRLs) - O Series

N-Generation Air Preparation Units

i. Thread Sizes:

M5, G1/8, G1/4, G3/8, G1/2, G3/4 and G1

ii. Combination Units:

Filter Regulator + Lubricator, Filter Regulator, Air Regulator, Air Lubricator, Air Filter and Micro Filter

iii. Modular Units:

For easy maintenance

iv. Accessories:

Wall and Panel Mounting Brackets, connecting nipples and pressure guages

v. Automatic Drain:

(Internal)

vi. Precision Regulators:

G1/8, G1/4, G1/2

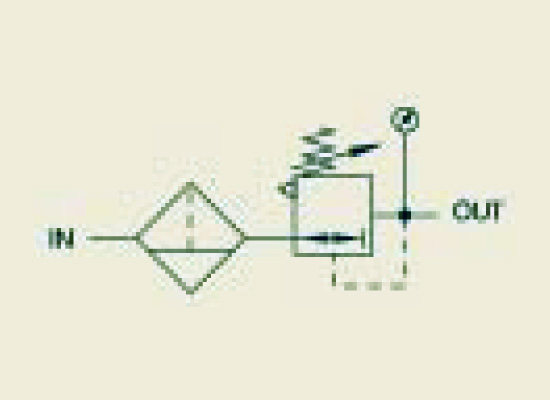

2. Filter Regulator / OFR

N-Generation Air Preparation Units

Filter and pressure regulator combine a single unit and cleans the compressed air of fluid oil, condensation and dirt particles. For special application, the standard 40µm filter element may easily be replaced by a 5µm filter element.

The OR maintain inputting constant operating pressure despite fluctuation in line pressure and the amount of air consumed.

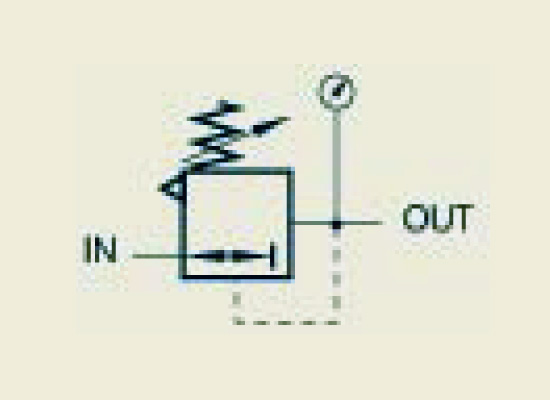

3. Regulator / OR

N-Generation Air Preparation Units

The OR maintain inputting constant operating pressure despite fluctuation in line pressure and the amount of air consumed.

4. Filter / OF

N-Generation Air Preparation Units

The OF water separator cleans the compressed air of fluid oil, condensation and dirt particles for special application, the standard 40µm filter element may easily be replaced by a 5µm filter element.

5. Lubricator / OL

N-Generation Air Preparation Units

The direct constant-density lubricator should be added regulated oil quality to the compressed air.

The valve maintains oil mist content proportional to the compressed oil flow.

The pressure drop that occurs when the air flow through a sight feed oil cup delivers oil from the bowl to the sight oil indicator. The drop of the oil flows into the air channel when it is atomized.

The oil drip rate is controlled by means of the regulating screw. Normally, 1 to 12 drop / 1000L of the air is sufficient.

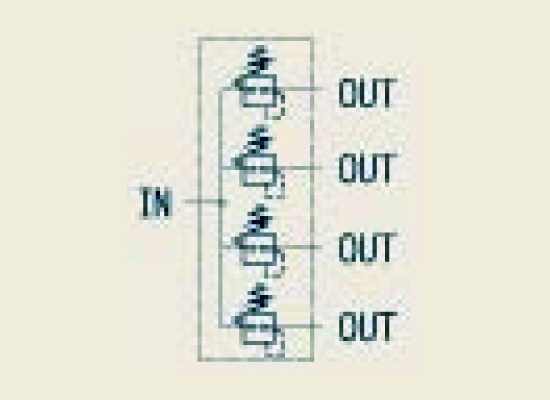

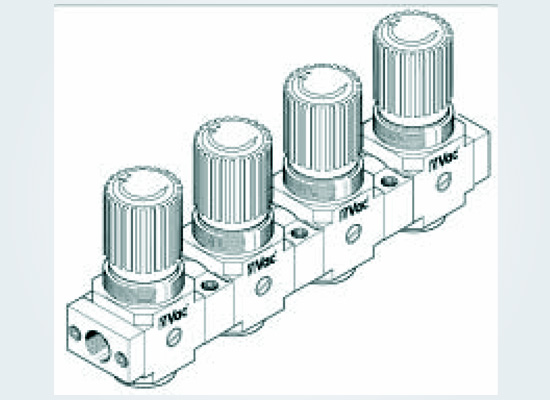

6. Pressure Regulator Combinations / ORB

N-Generation Air Preparation Units

The regulator for an integrated installation, can provide a variety of different pressure gas source, the front and rear sides of each one has an output connection.

Accessories

| Mounting Bracket - OHC | Manometer - OMA | Mounting Bracket - OHO | Branching Modules - FHM |

|---|---|---|---|

|

|

|

|

| Nut - HMR | |||

|

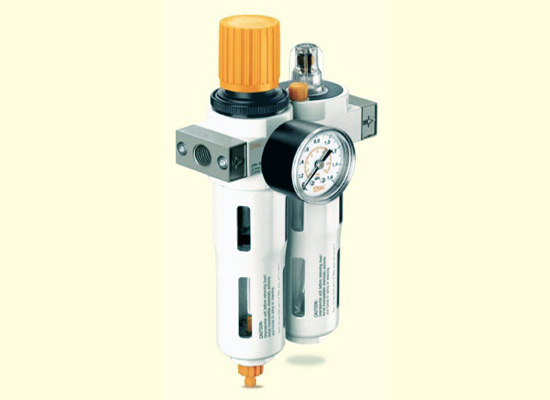

Filter, Regulator, Lubricator / OU

The OU consists of OFR and OL, each unit can be ordered separately. The OF with water separator cleans the compressed air of fluid oil, condensation and dirt particles. For special application, the standard 40µm filter element may easily be replaced by a 5µm filter element. The OR maintain inputting constant operating pressure despite fluctuation in line pressure and the amount of air consumed.

The proporational lubricator adds a regulated quantity of oil to the filtered air. The oil-mist content proporational to the flow and oil can be added during operation. The oil drip reate is controlled by the adjustable bolt. Normally, 1 to 12 drops / 1000L of air is sufficient.

Filter Regulator / OFR

Regulator / OR

Filter / OF

Lubricator / OL

Pressure Regulator Combinations / ORB